Fire-resistant fire protection system pipelines

Classification: Products

Keywords: polyester glass steel pipe, polyester glass steel pipe

The main products are: polyester glass fiber reinforced plastic pipe, epoxy glass fiber reinforced plastic pipe, glass fiber reinforced plastic equipment container, tower, flue, glass fiber reinforced plastic pultrusion molding profile and carbon fiber series and other high-performance fiber composite materials.

Fire-resistant fire protection system pipelines

Fire-resistant fire-fighting system pipeline is a new product independently developed on the basis of high-pressure epoxy glass fiber reinforced plastic pipeline used in oil fields and in combination with the fire-fighting and flame-retardant requirements of fire-fighting system. The system pipeline uses bisphenol A epoxy resin and imported curing agent as matrix materials, and high-strength alkali-free glass fiber as reinforcing materials and other auxiliary materials.

1. product features: high pressure resistance, anti-corrosion, long service life; light weight, easy installation and transportation; low friction coefficient, no scaling, excellent hydraulic characteristics; meet the extreme flame retardant requirements such as pool fire and jet fire; anti-static.

1, pipe fittings lining and outer protective layer is rich in resin, excellent corrosion resistance, durable, service life of not less than 30 years.

2. By optimizing the curing system and adding the processing technology of fireproof isolation layer in the outer layer, the system pipeline reached IMOA. 753(18) flame retardant requirements for three-level fire resistance and higher fire resistance ratings such as impact fire, furnace fire and jet fire.

3. The layup process of conductive fiber is added during molding, which not only ensures the conductivity, but also improves the strength and other performance indicators.

4, the installation is simple, rapid, convenient maintenance; due to light weight, easy handling, reduce the hoisting cost; there are a variety of connection methods, according to the specific construction conditions, flexible choice of joint mode, simple and rapid installation, low installation cost.

5. Excellent hydraulic performance, smooth inner surface, small wear resistance coefficient, good hydraulic characteristics, and wear resistance of the inner wall.

6. Flexible design and strong product adaptability. According to the user's various special requirements for use, for proprietary design and production.

2. size: 1.5 inches ~ 40 inches (DN40mm ~ DN1000mm), single length 30 feet (9m) or 40 feet (12m);

3. pressure rating: the highest 725PSI/5.0MPa;

4. working temperature: maximum 120 ℃;

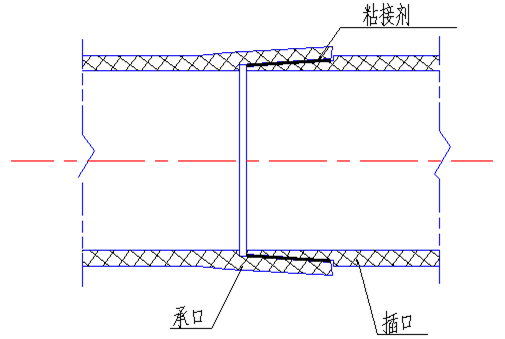

5. connection mode: socket adhesive Adhesive Bonded Joint, double O-ring socket connection Bell/Spigot Double O-RING Joint;

6. application scope: natural gas LNG, petrochemical, ship and offshore platform fire water supply pipeline;

7. implementation standards:

IMO A.753(18) Guidelines for the Use of Plastic Pipes on Ships Guidelines

IMO A.653(16) 《表面可燃性耐火试验程序建议 Recommendation on Improved Fire Test Procedures for Surface Flammability of Bulkhead, ceiling and Deck Finish Materials》

OTI 95634 《被动防火材料耐喷射火试验 Jet Fire “Jet Fire Resistance Test Of Passive Fire Protection Materials”(Health And Safety Executive(UK),Offshore Technology Report,1996》

8. socket bonding connection diagram:

Forging is a processing method that uses forging machinery to apply pressure to metal blanks to produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. Forging (forging and stamping) is one of the two major components. Forging can eliminate the defects such as loose casting in the smelting process and optimize the microstructure. At the same time, due to the preservation of the complete metal flow line, the mechanical properties of forgings are generally better than castings of the same material. Related machinery in high load, severe working conditions of important parts, in addition to the shape of a relatively simple available rolling plate, profile or welding parts, the use of forgings.

Previous Page

Previous Page

Related Downloads

Related Products

Online consultation

Pay attention to WeChat public number

Copyright©2023 Anhui xinhe new material co.,ltd | Business License | Powered By:300.cn | SEO

025-57492608

025-57492608