FRP process pipe

Classification: Products

Keywords: polyester glass steel pipe, polyester glass steel pipe

The main products are: polyester glass fiber reinforced plastic pipe, epoxy glass fiber reinforced plastic pipe, glass fiber reinforced plastic equipment container, tower, flue, glass fiber reinforced plastic pultrusion molding profile and carbon fiber series and other high-performance fiber composite materials.

FRP process pipe

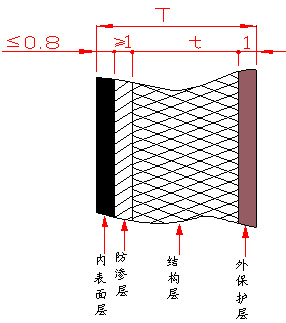

The glass fiber reinforced plastic process pipe is produced by reciprocating fiber winding process, with vinyl polyester resin as the matrix, alkali-free glass fiber yarn and its products as the reinforcing material, without adding any filler, according to the pre-designed line type and thickness, through microcomputer control winding wire production. Schematic diagram of glass fiber reinforced plastic process pipe wall structure:

1. performance characteristics

1. Excellent water resistance and corrosion resistance: scientific and reasonable resin selection and process design ensure that the pipeline has excellent waterproof, anti-seepage and chemical corrosion resistance.

2. Good mechanical properties and high specific strength: the tensile strength of glass steel pipe is ≥ 320Mpa; Impact resistance: the drop weight of 1.5kg will not be damaged under the impact height of 1.6m, and the specific strength is 3 times that of steel pipe, 10 times that of ductile iron pipe and 25 times that of concrete pipe.

3. Excellent temperature resistance: The long-term use temperature of glass steel pipe is generally -40 ℃ ~ 70 ℃. If high temperature resistant resin is selected, glass steel pipe can be operated for a long time under high temperature conditions of 120 ℃ and maintain good mechanical properties.

4. Small specific gravity, light weight, convenient transportation and installation: specific gravity is only 1/4~1/5 of steel and cast iron pipes and 2/3 of concrete; The weight is about 1/4 of the ductile iron pipe of the same specification and length and 1/10 of the concrete pipe. Therefore, the loading and unloading is convenient, easy to transport and install.

5, flexible interface, high security, a variety of interface types:

◆ "O" type seal ring socket connection (including lock key)

◆ Socket cementation

◆ Threaded connection

◆ Flange connection

◆ Butt wrapping

6. Low maintenance cost: FRP pipe has excellent corrosion resistance, wear resistance, anti-freezing and anti-fouling properties, so there is no need for special anti-rust, anti-fouling, insulation, heat preservation and other measures and maintenance. There is no need for cathodic protection for buried pipes, which can save engineering maintenance costs.

7. Long service life, safety and reliability: The design service life of glass steel pipe is based on 50 years, which is twice that of steel pipe and concrete pipe; for corrosive media, its service life is much higher than that of steel pipe.

8, flexible design, product adaptability: according to the user's various special requirements, by changing the design, to create a variety of specifications, pressure levels, stiffness levels or other special performance products, a wide range of applications.

2. execution standard

JC/T552-2011 Filament Wound Reinforced Thermosetting Resin Pressure Pipe

HG/T4372-2012-Pipes and Fittings of Composite Materials for Chemical Industry

HG/T21633-1991 FRP Pipe and Fittings

ASTM D3262-2006 《Specification for Fiberglass (Glass-Fiber-Reinforced Thermosetting-Resin) Sewer Pipe》

Forging is a processing method that uses forging machinery to apply pressure to metal blanks to produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. Forging (forging and stamping) is one of the two major components. Forging can eliminate the defects such as loose casting in the smelting process and optimize the microstructure. At the same time, due to the preservation of the complete metal flow line, the mechanical properties of forgings are generally better than castings of the same material. Related machinery in high load, severe working conditions of important parts, in addition to the shape of a relatively simple available rolling plate, profile or welding parts, the use of forgings.

Previous Page

Previous Page

Related Downloads

Related Products

Online consultation

Pay attention to WeChat public number

Copyright©2023 Anhui xinhe new material co.,ltd | Business License | Powered By:300.cn | SEO

025-57492608

025-57492608