FRP hairdryer

Classification: Products

Keywords: polyester glass steel pipe, polyester glass steel pipe

The main products are: polyester glass fiber reinforced plastic pipe, epoxy glass fiber reinforced plastic pipe, glass fiber reinforced plastic equipment container, tower, flue, glass fiber reinforced plastic pultrusion molding profile and carbon fiber series and other high-performance fiber composite materials.

FRP hairdryer

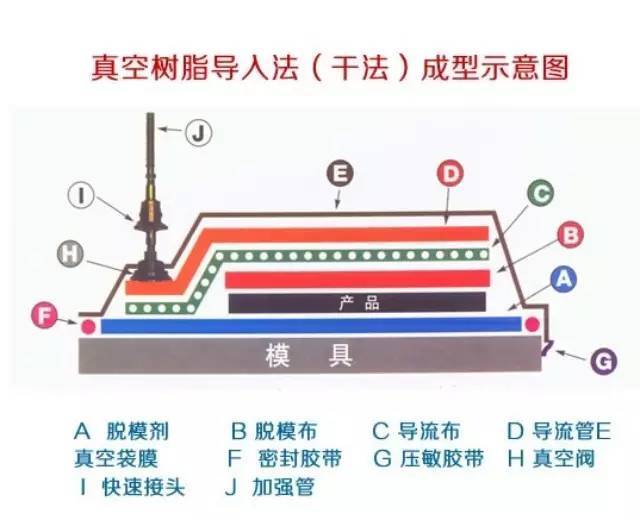

FRP ram (Fan Stack) is the enclosure and structural component of the cooling tower, which is formed by injection, film pressure, vacuum introduction of VIP and hand paste HLU process.

Process flow:

1, the use of professional materials and mechanical design technology, the use of high-precision CNC non-metallic engraving machine and grinding and polishing, to produce precision to meet international standards of mold. Mold features: high hardness, high efficiency, no deformation, not affected by temperature and humidity and other characteristics.

2. The gel coat is sprayed with imported glass fiber reinforced plastic special spraying equipment. After forming, it has significant advantages such as high surface finish, not easy to decolorization, anti-aging, anti-ultraviolet, and beautiful appearance.

3. The finished product uses corrosion-resistant, temperature-resistant and water-resistant resin and alkali-free glass fiber (yarn, felt, cloth) and other raw materials, and is made by VIP and HLU molding process. It has the characteristics of good wettability, high strength, no bubbles on the surface, and uniform color.

4. Flame retardant FRP air duct is made of flame retardant raw materials. The product is tested according to ASTM E-84, and the flame spread grade reaches 25 or lower.

5. The product assembly can be assembled in the factory or installed upright on site according to the height and shape.

Exquisite technology, perfect testing equipment, scientific and rigorous quality management system, to ensure that each set of products to meet the user's demanding.

Forging is a processing method that uses forging machinery to apply pressure to metal blanks to produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. Forging (forging and stamping) is one of the two major components. Forging can eliminate the defects such as loose casting in the smelting process and optimize the microstructure. At the same time, due to the preservation of the complete metal flow line, the mechanical properties of forgings are generally better than castings of the same material. Related machinery in high load, severe working conditions of important parts, in addition to the shape of a relatively simple available rolling plate, profile or welding parts, the use of forgings.

Previous Page

Next Page

Previous Page

Next Page

Related Downloads

Related Products

Online consultation

Pay attention to WeChat public number

Copyright©2023 Anhui xinhe new material co.,ltd | Business License | Powered By:300.cn | SEO

025-57492608

025-57492608